What Are Blast Gates?

A blast gate is a device used in dust collection systems to control the flow of air and debris through different branches or sections of the system. It is typically a sliding or rotating gate that can be opened or closed to regulate the airflow.

Dust collectors are used in dusty areas like a wood workshop, you can see our guide on designing and building your own dust collection system here.

The primary purpose of a blast gate is to direct suction and airflow to specific areas in a dust collection system. Dust collectors are often equipped with multiple inlet ports or branches that connect to different machines or workstations. By using blast gates, you can selectively open or close the gates to control which areas are actively collecting dust and which areas are not.

When a blast gate is closed, it blocks the airflow and prevents dust and debris from being drawn into the system through that particular branch. This is particularly useful when you are using only one machine or workstation and want to concentrate the suction power at that point, maximizing the efficiency of the dust collection process.

On the other hand, when a blast gate is opened, it allows the air and particles to pass through, enabling dust collection in the connected branch. By adjusting the positions of the blast gates, you can prioritize certain areas of the system and ensure that the dust collection capacity is distributed as needed.

Blast gates are often manually operated, meaning they require manual adjustment to open or close. However, there are also automated systems available that can control the blast gates electronically or pneumatically based on various factors like machine activation, sensor readings, or a pre-set schedule.

Overall, blast gates provide flexibility and control in dust collection systems by allowing you to direct airflow to specific areas, optimizing the efficiency of dust collection and minimizing the buildup of dust and debris in the workplace.

Getting Blast Gates

Blast gates can be purchased from various sources, including both physical stores and online retailers. Here are some options where you can find blast gates of different price ranges:

- Woodworking or Dust Collection Specialty Stores: Visit local woodworking supply stores or dust collection equipment retailers in your area. These stores often carry a wide range of blast gates suitable for various dust collection systems.

- Online Retailers: Several online retailers specialize in dust collection components and accessories. Here are a few popular options:

- Amazon (www.amazon.com)

- Grainger (www.grainger.com)

- Rockler (www.rockler.com)

- Woodcraft (www.woodcraft.com)

- Oneida Air Systems (www.oneida-air.com)

- Industrial Supply Companies: Look for industrial supply companies that cater to manufacturing or woodworking industries. They often have a comprehensive range of blast gates suitable for larger-scale dust collection systems.

When searching for blast gates, consider factors such as the size (typically specified in inches) to ensure compatibility with your dust collection system’s ducting, material quality, durability, and customer reviews to make an informed decision.

Remember to compare prices, read product descriptions, and check customer reviews to find the blast gates that meet your specific requirements and budget.

Cheap blast gates that most appeal to hobbyist woodworkers on Amazon can be purchased at $10-$12 apiece. They are cheaply assembled, injection molded parts. The gate, when closed, fits down into a slot to completely cut off airflow, but the slot is a closed area. Dust and chips inevitably settle in the slot and keep the gate from completely closing. This leaves a gap making every single blast gate eventually leak a significant amount of air. A better solution would be to let the gate continue down through the slot and out the other side of the gate. Then there is never an area for chips to build up.

There are gates that use this design but are more expensive, but there’s a better option for anyone with a 3D printer, print your own!

Making Your Own Blast Gate

Templates

Here are the design files I used. It was built in AutoDesk Inventor, and parts have been exported to laser cut some features and 3D print the connectors.

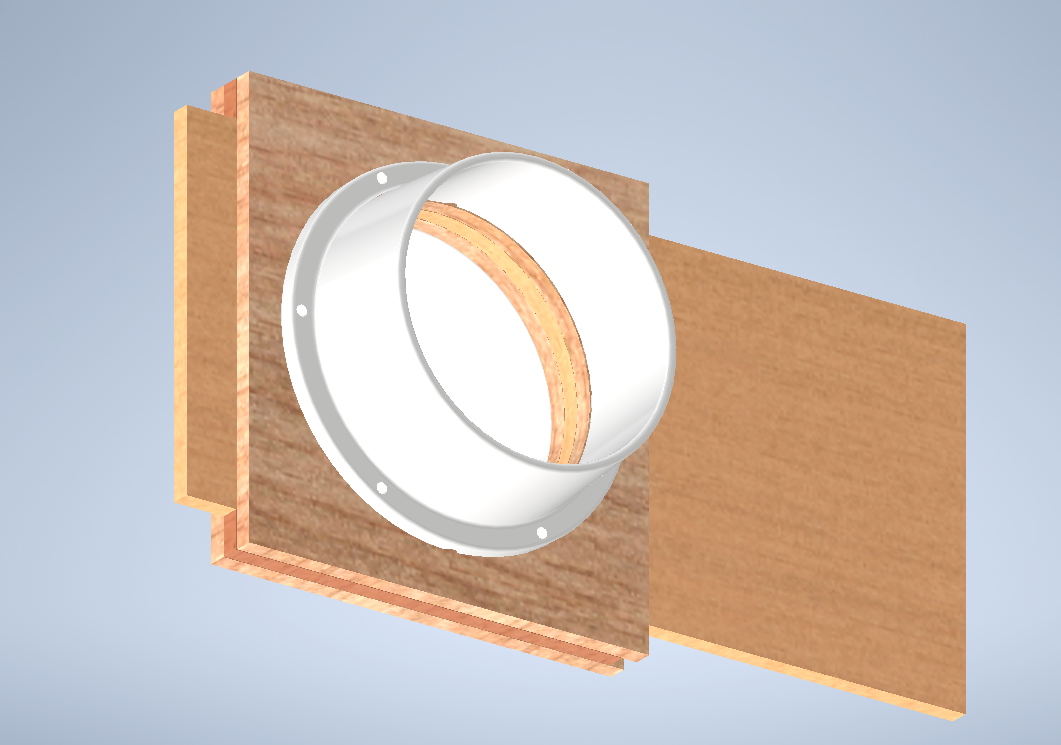

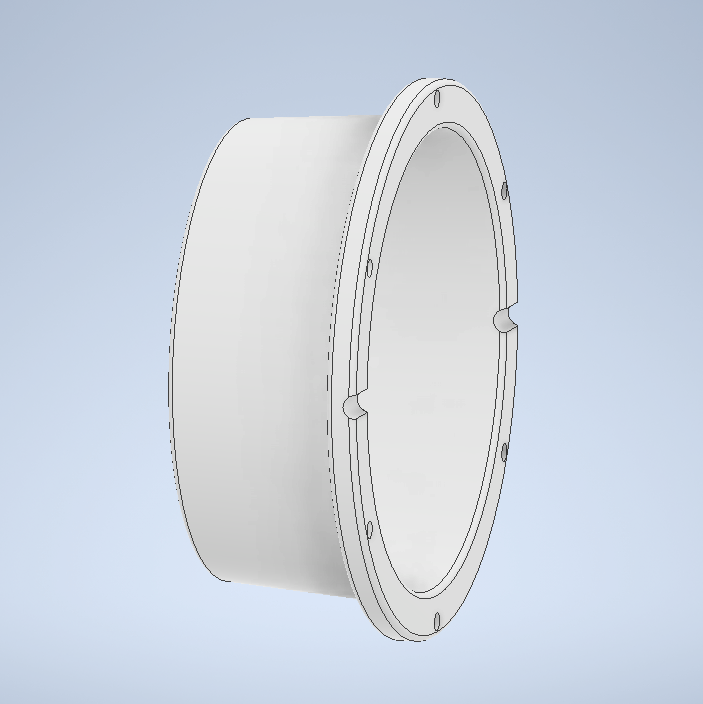

I have access to a laser cutter and a 3D printer, so I utilized them for what they do best. The gate and sides are simple parts, so I used the laser cutter to make those parts from cheap 1/4-inch plywood. The tapered connections for hoses to attach to are a little more complicated, so they were 3D printed.

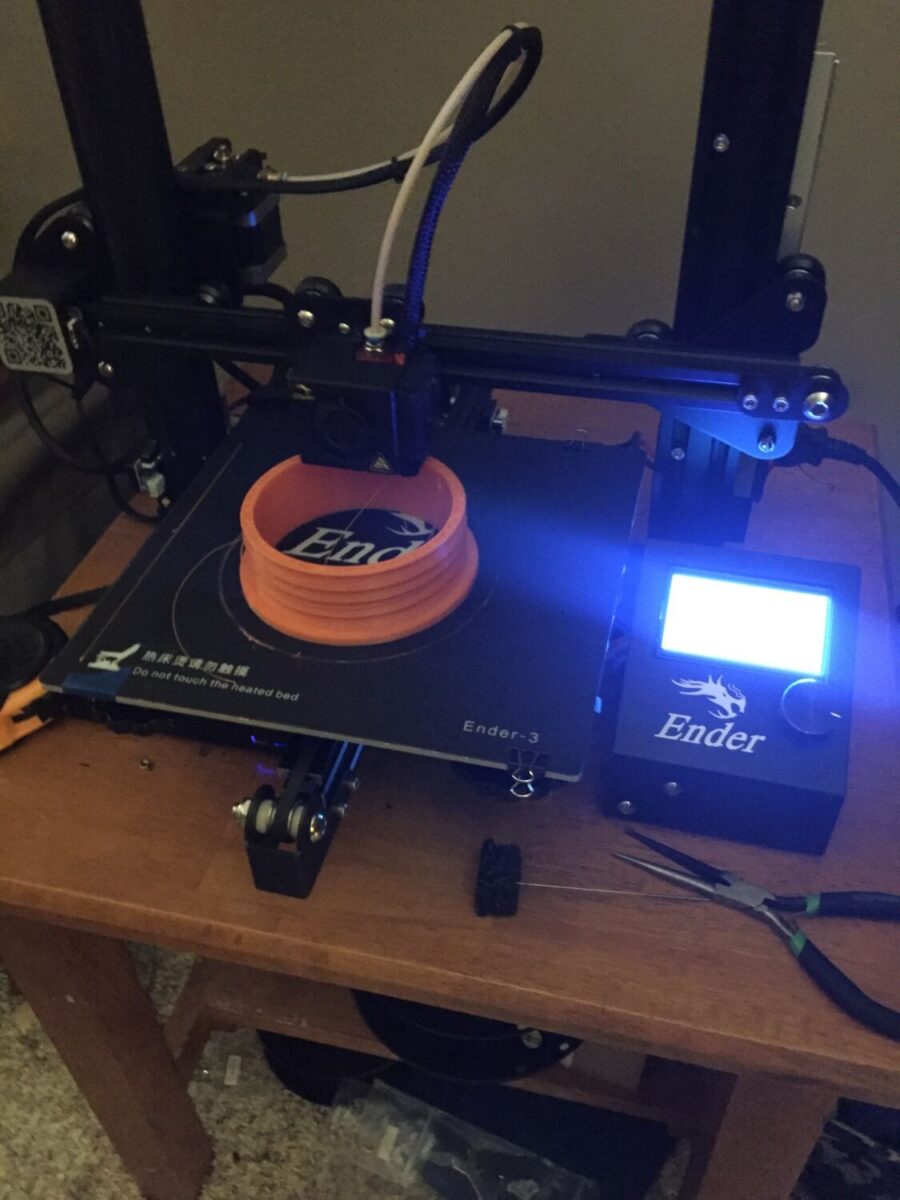

I have an Anycubic Photon Mono X printer, an LCD resin printer. It has some printing requirements, and the connection part was tailored to it. The connector has air gaps in the base, so it can be printed directly on the bed of any resin printer. Additionally, the connection comes with bolt holes for attaching, but I had better luck just using CA glue for mounting.

You also need to print or attach 4.8″ x 0.5″ x 0.5″ blocks to the gate to keep it from sliding out of the blast gate. I made these from the wood I had lying around.

One final note on assembly, alter the 3D design to make the sides of the gate thicker, or assemble the side strips with a piece of paper on top to add clearance for the gate to move easily.

Results

After printing, cutting, and assembling, you are left with a 4″ compatible blast gate that is easy to use and doesn’t leak air. It doesn’t clog with chips. I never calculated the cost of these blast gates, but the 3D prints used about 100 mL of resin per gate, and the wood parts were cut from 12″ x 24″ of plywood per gate. Estimating the cost, I paid about $3 in resin per gate and $1 in plywood, so it was significantly cheaper than any blast gate that could be found online.

Informative articles. I use the cheap plastic gates. Saw off the ends to allow dust/chips to push out when closing. Duct tape seal on sawed off end seals the end of the gate when opened. Lots of videos online about this.

Neat idea! Definitely much simpler to implement. I chose this method because at the time, money was more valuable than time spent on the project.